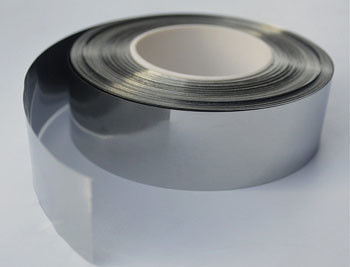

- Ni2 high purity nickel film, Ni6 imports of pure nickel

- Alloy with nickel as the base to add other elements. After 1905 the prepared copper containing about 30% of Monel alloy (Monel), nickel alloy is earlier

- . Nickel has good mechanical, physical and chemical properties, adding suitable elements can improve its oxidation resistance, corrosion resistance, high temperature strength and improve

- Some physical properties. Nickel alloy can be used as electronic materials, precision alloy (magnetic alloy, precision resistance alloy, electric heating alloy, etc.), nickel base

- High temperature alloys, nickel based alloys, shape memory alloys, etc.. In energy development, chemical, electronics, navigation, aviation and aerospace and other departments,

- Nickel alloys are widely used.

- British scientists use the etching technology, with nitric acid soaking with a moderate amount of phosphorus element of the nickel alloy, to produce a very low reflectivity of the ultra black surface material

- Material, this is the world's most known black material.

- Iron and nickel can form a variety of alloys with copper, iron, manganese, chromium, silicon and magnesium, which is famous for its high strength, good plasticity and good plasticity, and in the 750 degree of the alloy.

- In the atmosphere, chemical properties are stable, and are widely used in electrical industry, vacuum tube, chemical industry, medical equipment and marine industry.

- Note: cutting process difficulty.

Application and classification of 2 nickel alloys

By use

Nickel base superalloy. The main alloying elements include chromium, tungsten, molybdenum, cobalt, aluminum, titanium, boron, zirconium, etc.. Which chromium from the oxidation and corrosion resistance,

Other elements play a role. At 650 ~ 1000, the high strength and oxidation resistance, corrosion resistance, and high temperature alloy should be

A class of alloys with the highest and high temperature strength. The talent is scarce mainly in iron and steel co.. Used in the manufacture of aero engine blades

High temperature components on chip and rocket engine, nuclear reactor, energy conversion equipment.

Ni base corrosion resistant alloy. The main alloying elements are copper, chromium and molybdenum. Has a good overall performance, resistant to acid corrosion and stress corrosion. The earliest

Is the application of nickel copper alloy, also called Monel alloy; in addition to the Ni Cr alloy, Ni Mo alloy, nickel chromium molybdenum alloy etc.. Used to manufacture all kinds of resistance

Corrosion parts.

Nickel base wear resistant alloy. The main alloying elements are chromium, molybdenum and tungsten, which also contain a small amount of niobium, tantalum, and indium. In addition to the wear resistance, its antioxidant

, corrosion resistance, welding performance. Can manufacture wear-resistant parts, can be used as coating material, through the welding and spraying process will be covered in other

Substrate material surface.

The nickel base alloy precision. Including nickel based soft magnetic alloy, nickel based precision resistance alloy and nickel based alloy, etc.. The most commonly used soft magnetic alloys are nickel bearing

About 80% of the permalloy, the maximum initial permeability and high permeability and the coercivity is low, core plays an important role in the electronic industry. Nickel base

The main alloy elements of the dense resistance alloy are chromium, aluminum and copper, which have high resistivity, low resistivity temperature coefficient and good

Corrosion resistance, used in the manufacture of resistors. Nickel base alloy is 20% chromium nickel alloy, which has

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!